Complete Guide to Gate Valves: Types, Components, Materials & Applications

- Home

- »

- Technical Guides

- »

- Gate Valve Types, Stem Designs & Materials Explained

Table of Contents

Introduction

Gate valves are essential components in fluid control systems, widely used across various industries, from water supply and plumbing to oil and gas pipelines. This comprehensive guide explores different types of gate valves, their structural components such as the gate valve stem, materials like carbon steel and stainless steel, and the differences between knife gate valves vs gate valves. Whether you’re an engineer, a plumber, or a procurement professional, this guide will help you make informed decisions about plumbing gate valves and water supply valve types.

Types of Gate Valves

Gate valves can be classified based on disc type, stem design, and seat material. Here are the most common types:

Gate Wedge Valve: This is the most popular design. It features a tapered disc (wedge) that fits between two seat rings, providing tight shutoff.

Resilient Seated Gate Valve: Instead of metal-to-metal seating, these use a rubber-coated wedge, ensuring bubble-tight sealing even in low-pressure systems.

Rising Stem Gate Valve: The stem rises above the handwheel during operation, making it easy to see whether the valve is open or closed.

Non-Rising Stem Gate Valve: In this design, the stem rotates within the valve, ideal for tight spaces or buried service applications.

Knife Gate Valve: These are designed for slurry or viscous fluids. The sharp-edged gate can cut through thick flow.

Gate Valve Stem and Operating Mechanism

The gate valve stem connects the handwheel to the gate. In rising stem gate valves, the stem moves vertically, clearly indicating valve position. These are often used in outdoor or industrial applications where visibility of valve status is critical.

Non-rising stem designs are enclosed and ideal for underground, confined, or space-constrained installations. The selection between rising and non-rising stems depends on space availability and operational visibility needs.

Gate Valve Diagram and Key Components

Understanding the internal structure helps in maintenance and selection. A standard gate valve diagram includes:

Body: The main casing holding all internal parts.

Bonnet: Covers the stem and packing, bolted to the body.

Gate/Wedge: The disc that moves up or down to control flow.

Stem: Transfers motion from the handwheel.

Seat: Provides sealing surface for the gate.

Packing: Prevents leakage along the stem.

This layout is crucial for troubleshooting and repair procedures.

Material Options: GGG40, GGG50, Stainless Steel, Carbon Steel

Selecting the appropriate gate valve material ensures optimal performance, durability, and cost-effectiveness across different applications:

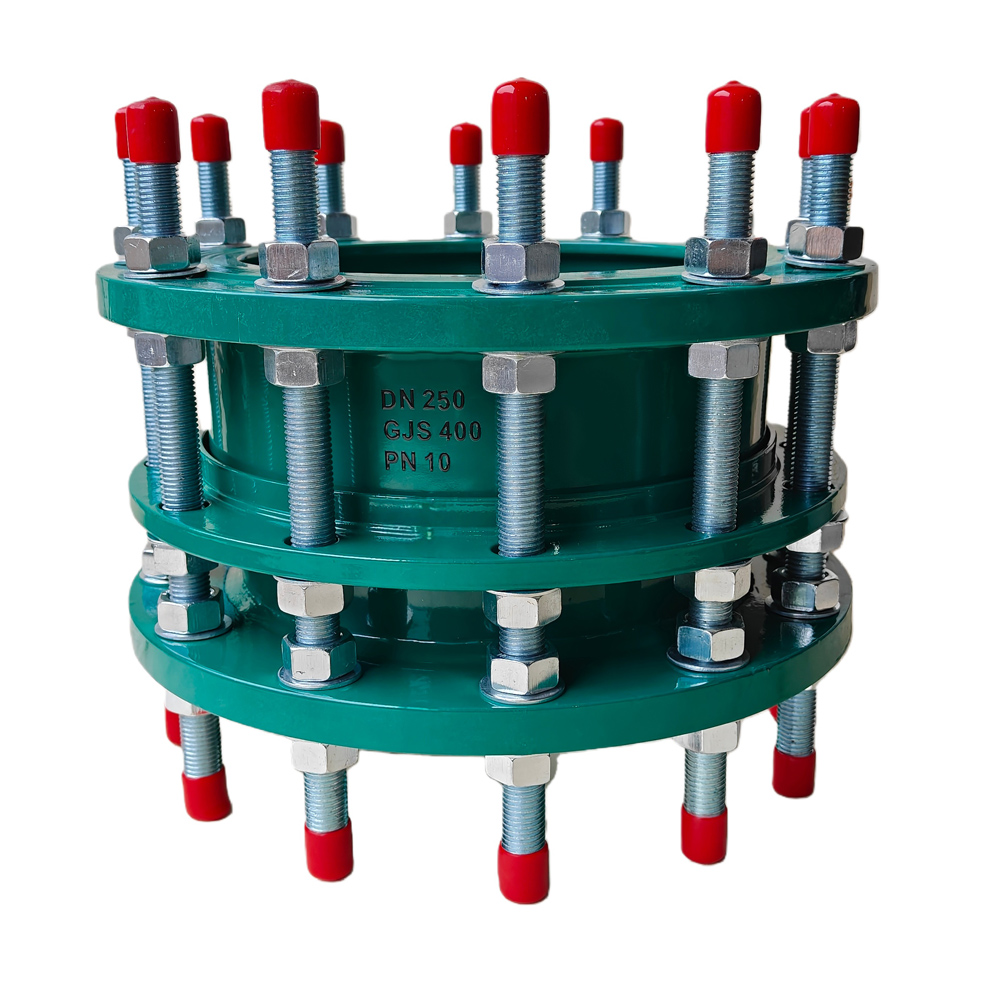

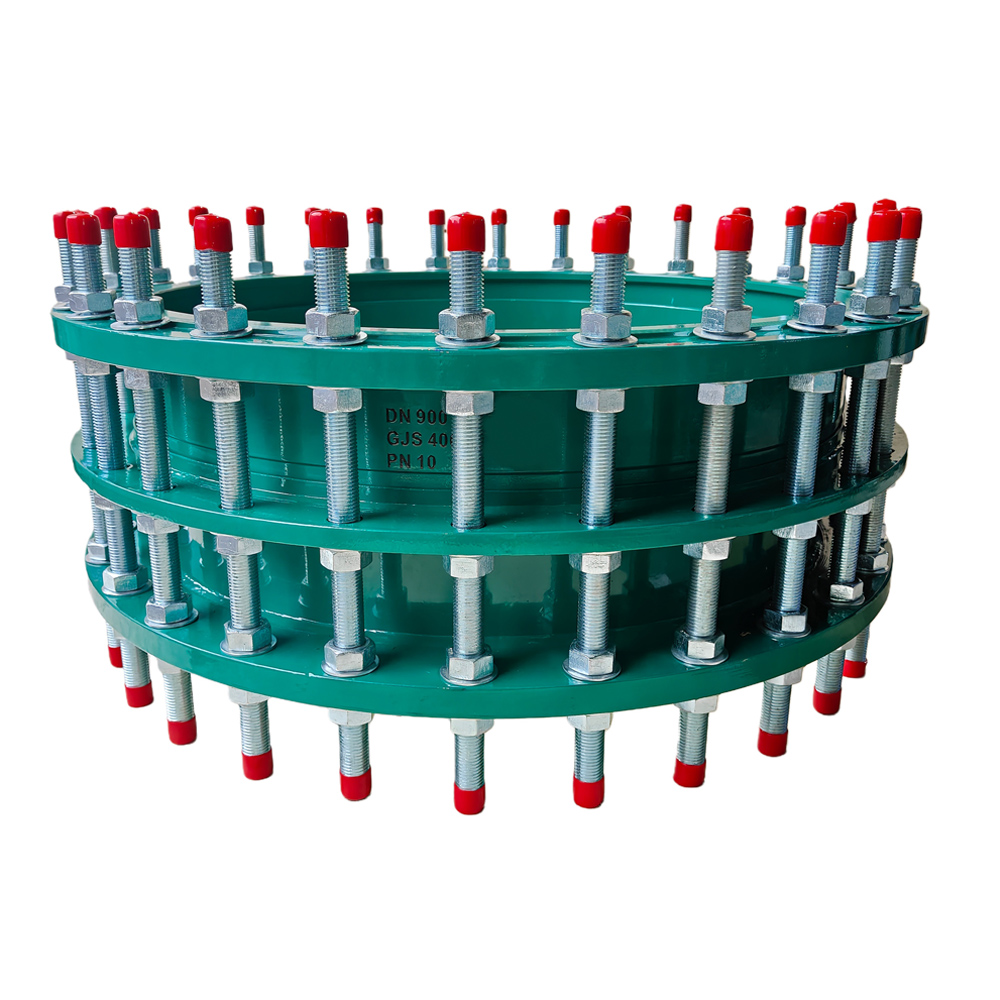

GGG40 (Ductile Iron EN-GJS-400-15)

GGG40 is a ductile iron grade known for good tensile strength, ductility, and impact resistance. It’s widely used in general-purpose water systems, municipal pipelines, and low-to-moderate pressure industrial applications. It offers a great balance of strength and cost for standard environments.GGG50 (Ductile Iron EN-GJS-500-7)

GGG50 offers higher mechanical strength than GGG40 and is ideal for more demanding industrial conditions, such as waterworks under higher pressure or systems with moderate abrasion. It maintains toughness while improving resistance to stress and mechanical loads.Stainless Steel (SS Gate Valve)

Stainless steel (commonly SS304 or SS316) gate valves are corrosion-resistant and hygienic, making them suitable for chemical processing, food and beverage systems, seawater applications, and pharmaceutical pipelines. They withstand extreme temperatures and aggressive cleaning agents, making them ideal for critical or sanitary environments.Carbon Steel (CS Gate Valve)

Carbon steel gate valves are engineered for high-pressure, high-temperature service—typical in oil & gas, power generation, and steam systems. While not as corrosion-resistant as stainless steel, carbon steel offers excellent strength, toughness, and resistance to thermal stress.

Applications: Gate Valves for Water and Plumbing

Gate valves are highly versatile and are used in the following areas:

Gate Valves for Water: Installed in municipal water systems, irrigation lines, and water treatment plants for isolating flow.

Plumbing Gate Valves: Common in residential and commercial plumbing systems to shut off water during repairs or upgrades.

Their ability to provide minimal pressure drop and tight shutoff makes them suitable for water supply valve types.

Types of Water Supply Valves and the Role of Gate Valves

In any residential, commercial, or municipal water system, a range of valve types is used to control, isolate, or direct water flow. Understanding these water supply valve types helps ensure the correct valve is selected for safety, efficiency, and long-term operation.

Common Water Supply Valve Types:

Gate Valves

Designed for full open or full closed service, gate valves offer minimal flow restriction and are ideal for large-diameter pipelines. Their robust construction makes them suitable for municipal mains, irrigation networks, and pump stations.Ball Valves

These valves provide a quick quarter-turn operation and tight shutoff, making them ideal for applications requiring frequent on-off cycles. However, they’re less suitable for throttling.Globe Valves

Globe valves are primarily used to regulate flow. Their flow path is not as straight as gate valves, resulting in higher pressure drops, but their throttling accuracy makes them valuable in water mixing or modulation.Check Valves

Check valves allow water to flow in only one direction and automatically prevent backflow. They are essential in pump systems and distribution lines.Butterfly Valves

Often used in larger water systems, butterfly valves are compact and lightweight with low torque requirements. They’re great for shutoff and some throttling duties.

Knife Gate Valve vs Gate Valve

While both perform shutoff functions, they serve different purposes:

Knife Gate Valve: Slimmer profile with a sharp edge, ideal for handling slurry, wastewater, and pulp applications where solid particles are present.

Standard Gate Valve: Better suited for clean media like potable water or gas and provides better sealing performance.

If your system deals with abrasive or viscous fluids, go with a knife gate valve. For general flow isolation, choose a standard gate valve.

Conclusion

Understanding the types of gate valves, their materials, internal components like the gate valve stem, and their applications in plumbing gate valves or water supply valve types is crucial for selecting the right product. Whether it’s a resilient seated gate valve for a city water line or an SS gate valve for a corrosive factory process, JHY Group provides a complete range of industrial gate valves to meet your needs.

Browse our product catalog or contact our valve experts to find the perfect valve solution for your pipeline system.