What Is a Gate Valve Used For? Industrial Applications Explained

- Home

- »

- Technical Guides

- »

- What Is a Gate Valve Used For? Industrial Applications Explained

Table of Contents

Introduction

A gate valve is one of the most common shut-off valves used in plumbing, water supply systems, and industrial pipelines. Its primary function is to start or stop the flow of liquid by raising or lowering a gate inside the valve body. In this article, we explain what a gate valve is used for, the different gate valve types, key components of gate valves, and when to consider gate valve repair or replacement.

What Is a Gate Valve Used For?

Gate valves are widely applied in situations where a full flow of liquid or complete shut-off is required. They are not suitable for throttling (regulating flow), but they are excellent for isolation. Common uses include:

Water supply systems – municipal and industrial water lines.

Oil and gas pipelines – to isolate sections for maintenance.

Power plants – steam lines and cooling water.

Plumbing systems – as main water gate valves in buildings.

RV and sewer systems – using RV gate valves for wastewater control.

If you want to learn more about how these valves function, check out our detailed guide: How Does a Gate Valve Work?

Types of Gate Valves

There are several gate valve types, each designed for specific conditions:

Rising Stem Gate Valves – stem moves up when opened (visual position indicator).

Non-Rising Stem Gate Valves – stem stays fixed; used in underground applications.

Solid Wedge vs Flexible Wedge Valves – designed for different pressures and sealing conditions.

Specialty Valves – such as globe vs gate valve or ball valve vs gate valve alternatives.

See our in-depth article: Gate Valve Types, Stem Designs & Materials Explained.

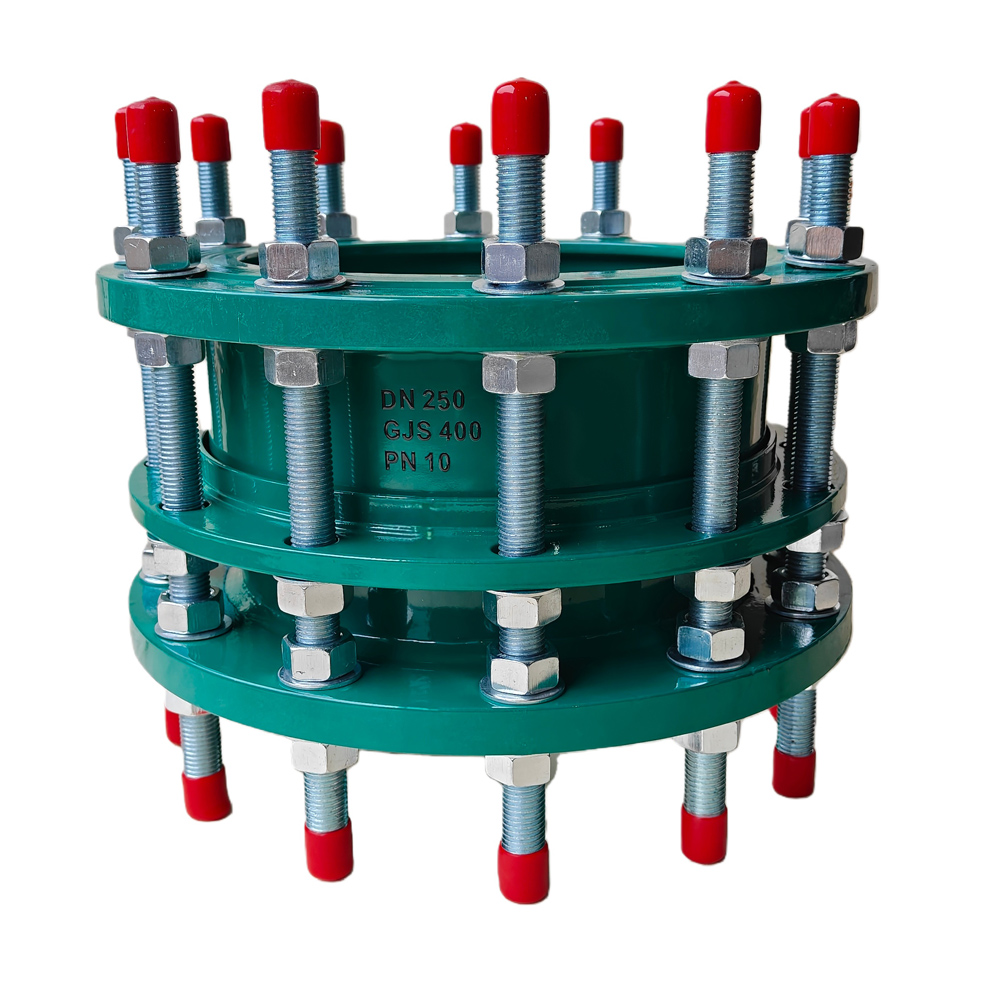

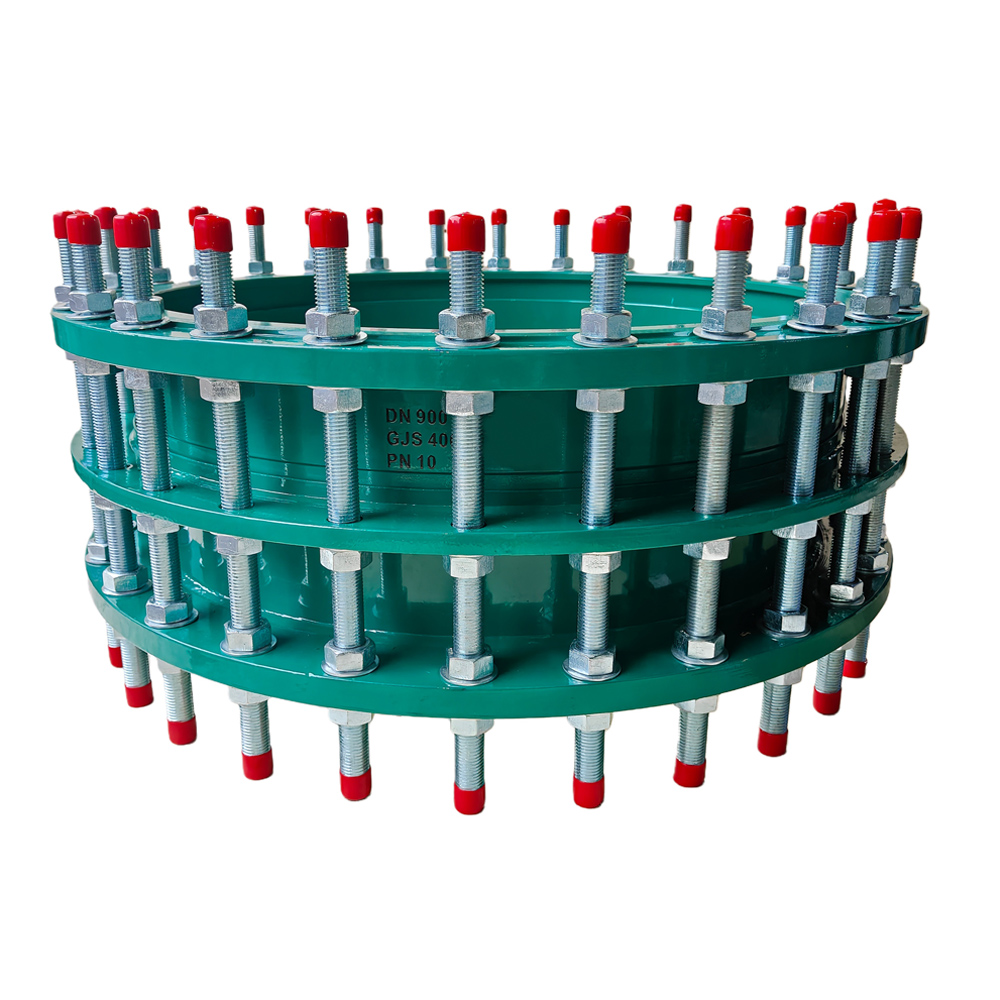

Parts and Components of a Gate Valve

Before understanding its applications, you should know the parts of a gate valve:

Body – the outer casing.

Stem – transfers motion.

Gate/Disc – blocks or allows flow.

Seat – provides a sealing surface.

Packing Gland – prevents leakage.

For a complete breakdown, read our guide: Gate Valve Components and Parts Explained.

When to Repair or Replace a Gate Valve

When replacement is necessary, selecting the right gate valve manufacturers or a reliable gate valve supplier ensures long service life. Industrial users often prioritize material quality, certification, and after-sales support.

For a practical step-by-step guide, see our article: Gate Valve Repair and Replacement Guide.

Choosing the Right Manufacturer or Supplier

When replacement is necessary, selecting the right gate valve manufacturers or a reliable gate valve supplier ensures long service life. Industrial users often prioritize material quality, certification, and after-sales support.

Explore our list of Top Gate Valve Manufacturers and Suppliers.

Conclusion

So, what is a gate valve used for? From water pipelines and industrial plants to plumbing and RV systems, gate valves are critical shut-off devices. By understanding gate valve components, knowing when to choose repair vs replacement, and selecting the right supplier, you can ensure your system runs efficiently.