Gate Valves for Water Supply and Wastewater Treatment

- Home

- »

- Technical Guides

- »

- Gate Valves for Water Supply and Wastewater Treatment

Table of Contents

Introduction

Gate valves are among the most widely used flow control devices in modern water supply and wastewater treatment systems. Designed for reliable shut-off, a gate valve provides full-bore opening with minimal pressure drop, making it ideal for clean water, raw water, and sewage pipelines. Whether in large municipal projects or industrial facilities, gate valves for water play a critical role in maintaining safe and efficient operation.

Why Gate Valves Are Essential in Water Supply

In potable water networks, a water gate valve ensures dependable isolation when maintenance or repair is required. Common designs include:

Flanged gate valves, preferred for high-pressure pipelines.

Rising stem gate valves, which clearly indicate open or closed position.

Non rising stem gate valves (NRS), widely used in underground installations where space is limited.

Engineers and gate valve manufacturers often recommend ductile iron and stainless steel gate valves for their durability, corrosion resistance, and long service life.

Gate Valves in Wastewater Treatment Applications

Wastewater pipelines carry abrasive and corrosive media. To handle such conditions, plants rely on heavy-duty wedge gate valves, sliding gate valves, or even double disk gate valves for precise shut-off. Specialized designs like MJ gate valves (M&J gate valves) and OS&Y gate valves (Outside Screw & Yoke) are often used in treatment plants and pumping stations.

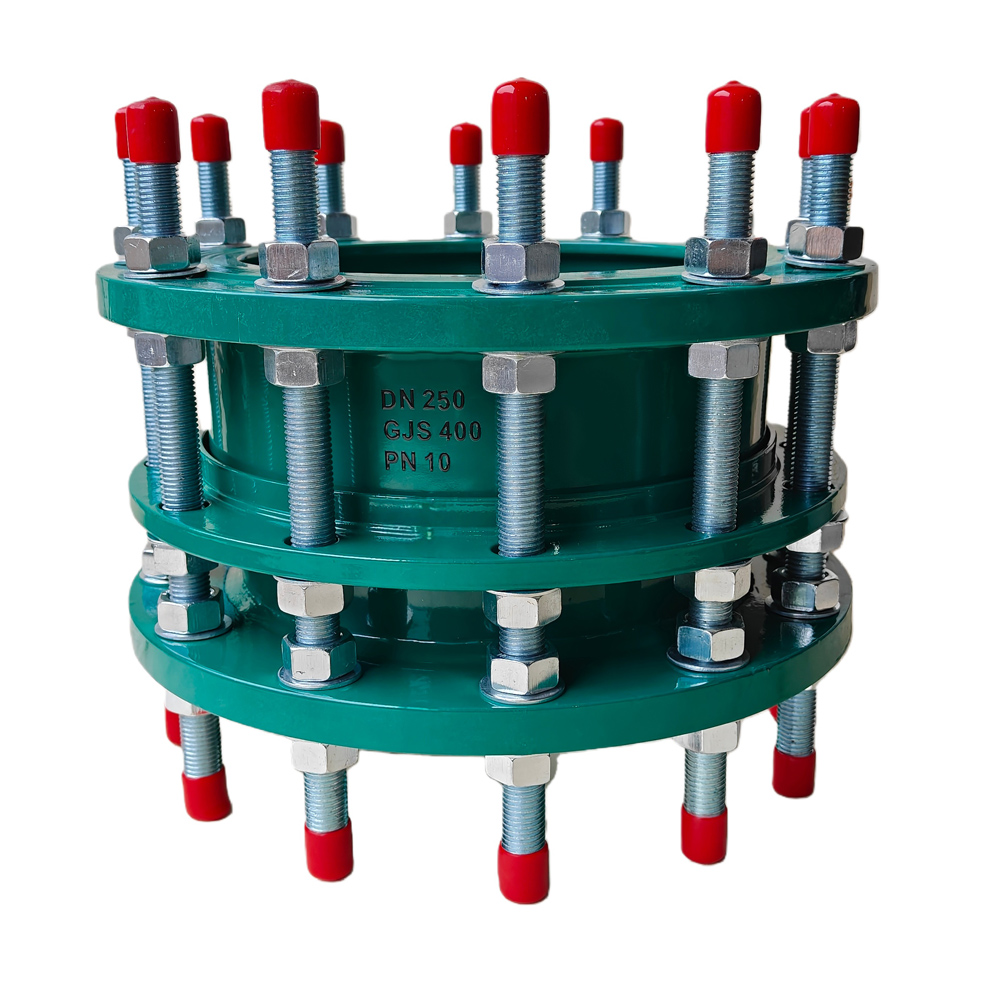

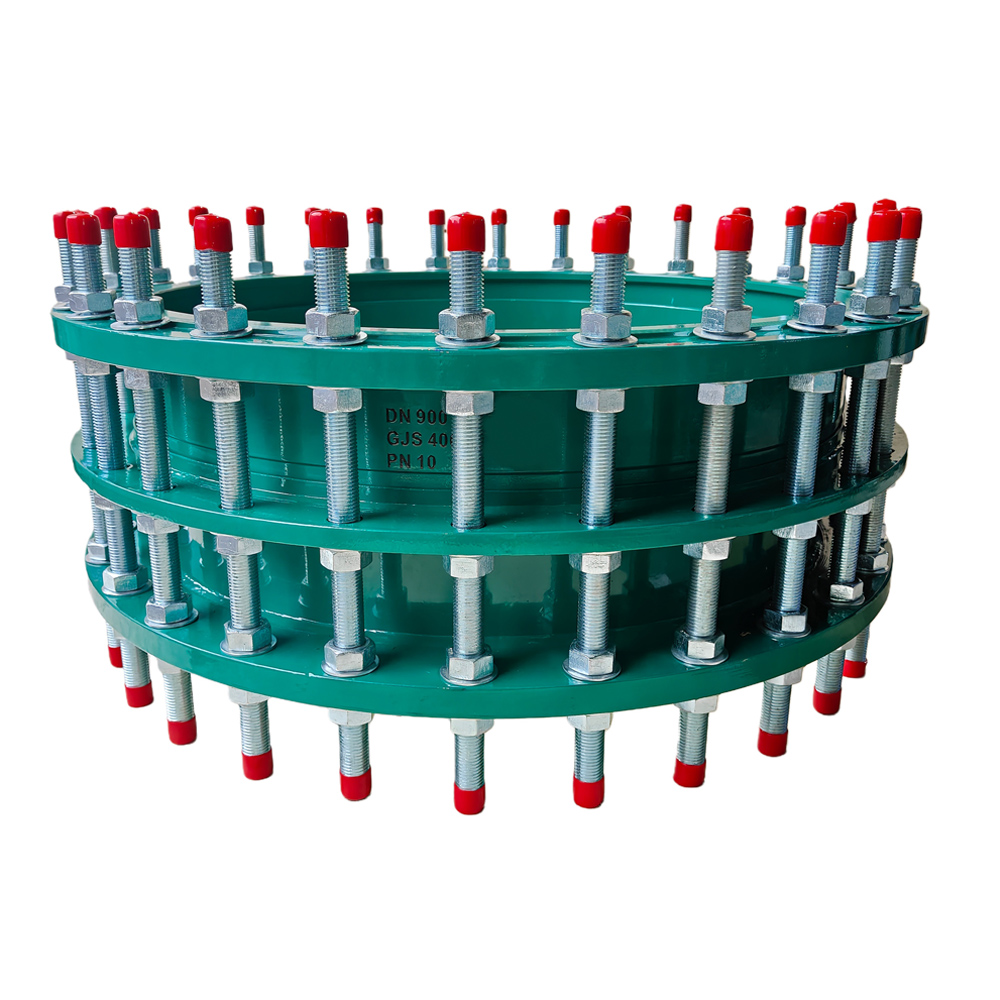

Available Sizes and Specifications

Gate valves are manufactured in a wide range of diameters to suit different pipeline requirements:

1/2 inch gate valve to 2 inch gate valve for small domestic or light industrial pipelines.

3 inch flanged gate valve and 4 inch flanged gate valve for medium systems.

6 inch gate valve, 12 inch gate valve, and even 24 inch gate valves for large-scale water and wastewater projects.

PVC options such as 2 inch gate valve PVC and 4 inch gate valve PVC for low-pressure and chemical applications.

Leading gate valve suppliers offer complete catalogs with variations in body materials (ductile iron, stainless steel), stem designs (rising stem, non-rising stem), and connection types (flanged, threaded, mechanical joint).

Cost and Availability

The cost of gate valves depends on size, material, and design. For example, a 6 inch gate valve price may vary based on whether it is ductile iron or stainless steel. Many gate valves for sale are available directly from gate valve manufacturers and suppliers, making it easier for buyers to source reliable products at competitive prices.

Choosing the Right Valve for Your System

When deciding between different valve types, engineers often compare gate valve vs butterfly valve or even plug valve vs gate valve. While butterfly valves are compact and cost-effective, gate valves are superior when full unobstructed flow or tight shut-off is required. In water distribution systems, a shut off gate valve ensures safety and operational control.

Conclusion

Gate valves remain one of the most trusted solutions for water supply and wastewater treatment. With options ranging from 1/2 inch to 24 inch gate valves, buyers can choose from ductile iron gate valves, stainless steel gate valves, or specialized models like OS&Y and NRS designs. Whether you are sourcing from top gate valve manufacturers, looking for gate valves for sale, or researching what is a gate valve, this versatile valve type provides unmatched reliability across industries.