Ball Check Valve

- Prevents Backflow: The ball check valve effectively prevents reverse flow, ensuring the integrity of the system.

- Minimal Pressure Drops: Designed to maintain efficient flow with minimal resistance, reducing pressure drops in the system.

- Durable Construction: Available in robust materials like cast iron and stainless steel for long-lasting performance in various environments.

- Self-Operating Mechanism: Automatically operates based on differential pressure, requiring no external actuation.

- Versatile Installation: Suitable for both horizontal and vertical piping configurations, offering flexibility in system design.

- Corrosion Resistance: Options like stainless steel balls and valve bodies provide excellent resistance to corrosive fluids.

- Low Maintenance: Simple design with fewer moving parts, leading to reduced maintenance requirements and downtime.

- Rapid Closure: Optional spring-loaded designs for faster response times, minimizing the risk of water hammer and other flow issues.

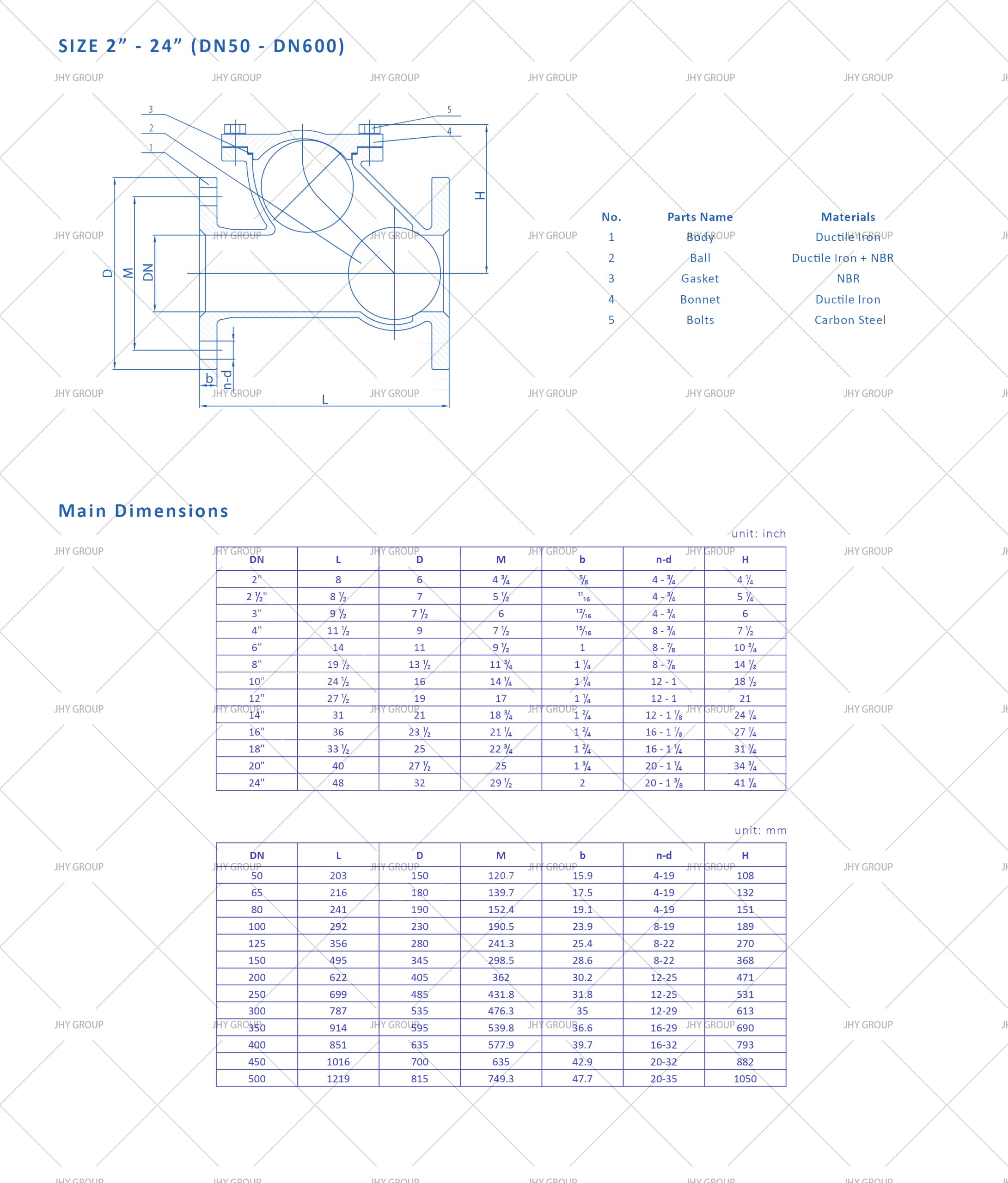

| Attribute | Details |

|---|---|

| Size Range | 2″ – 24″ |

| Pressure Rating | 250 psi |

| Working Temperature | -10˚C ~ +80˚C -50˚F ~ +176˚F |

| End Connection | ANSI B16.1 / ANSI B16.5 |

| Face-to-Face | AWWA C508 |

| Test & Inspection | AWWA C508 / API 598 |

| Body | Ductile Iron |

| Ball | Ductile Iron + NBR Encapsulated |

Understanding the Design of Ball Check Valves

Ball check valves are a versatile type of check valve designed to prevent reverse flow in piping systems. Unlike other check valve types, a ball check valve uses a spherical ball as the closing mechanism. The ball is positioned within the valve body and moves freely along the flow path, allowing fluid to pass through when the pressure is sufficient. When the pressure drops or reverse flow occurs, the ball rolls back to seal against the valve seat, effectively preventing any backflow.

The simplicity of the ball check valve design makes it an ideal choice for systems where maintenance needs to be minimized. The valve’s operation is entirely automatic, requiring no external actuation. This self-operating nature is particularly beneficial in applications where reliable and consistent flow control is critical.

Key Components and Materials

A ball check valve typically consists of several key components, including the valve body, ball, and valve seat. The valve body is often made from durable materials like cast iron or stainless steel, depending on the application’s requirements. Cast iron is commonly used in general-purpose applications due to its strength and cost-effectiveness, while stainless steel is preferred for more demanding environments where corrosion resistance is essential.

The ball itself is usually made from materials that can withstand the specific fluid properties and operating conditions of the system. Stainless steel balls are commonly used in applications involving corrosive fluids or high temperatures. The valve seat, which the ball seals against, is designed to ensure a tight closure, preventing any leakage even under high pressure.

How Ball Check Valves Operate

Ball check valves operate based on the principle of differential pressure. When fluid flows through the valve in the correct direction, the pressure pushes the ball away from the valve seat, allowing the fluid to pass through. This process occurs with minimal resistance, making ball check valves suitable for systems with low-pressure drops.

In the event of reverse flow, the pressure on the downstream side of the valve pushes the ball back against the valve seat, effectively closing the valve and preventing backflow. The speed at which the valve closes can be influenced by factors such as the size of the ball, the valve seat design, and the system’s overall pressure. For applications where rapid closure is necessary, spring-loaded or spring-assisted designs can be used to increase the valve’s responsiveness.

Applications of Ball Check Valves

Ball check valves are widely used across various industries due to their simplicity and effectiveness in preventing backflow. In water treatment systems, they help maintain pump capacity by preventing the reverse flow of water. The minimal pressure drop associated with ball check valves ensures that the system operates efficiently, without unnecessary strain on the pumps.

In industrial applications, ball check valves are often installed in systems that handle corrosive fluids or require frequent opening and closing. Their robust design and ability to handle both horizontal and vertical installations make them a versatile solution for various piping configurations.

Advantages of Using Ball Check Valves

One of the key advantages of ball check valves is their ability to handle a wide range of fluid types and conditions. The ball’s movement is unrestricted, allowing it to respond quickly to changes in flow direction. This rapid response helps to prevent issues like water hammer, which can occur when a valve closes too slowly, causing pressure surges within the piping system.

Additionally, ball check valves are known for their durability and low maintenance requirements. The use of materials like cast iron and stainless steel ensures that the valve can withstand harsh operating conditions, providing long-term reliability. The simple design also means that there are fewer components to wear out or fail, reducing the need for frequent repairs or replacements.

Selecting the Right Ball Check Valve

When selecting a ball check valve for your application, it’s important to consider factors such as the fluid properties, operating pressure, and installation orientation. For systems that require a high degree of corrosion resistance, stainless steel valves are recommended. If minimizing pressure drops is a priority, choosing a valve with a well-designed seat and an appropriately sized ball is essential.

In systems where reverse flow could cause significant damage, such as in pumps or sensitive equipment, it may be beneficial to opt for a spring-loaded or spring-assisted ball check valve. These designs ensure faster closure times, reducing the risk of backflow and associated problems.

Conclusion: Ensuring Reliable Flow Control with Ball Check Valves

In summary, ball check valves play a crucial role in maintaining the integrity and efficiency of piping systems by preventing backflow. Their simple yet effective design, combined with the use of durable materials like cast iron and stainless steel, ensures long-term reliability in a wide range of applications. Whether you’re dealing with high-pressure systems, corrosive fluids, or complex piping configurations, a well-chosen ball check valve can provide the peace of mind and performance you need.

For more information on selecting the right ball check valve for your specific application, explore the comprehensive product line offered by Jhy Group. You can also browse our entire product catalog to discover additional flow control solutions tailored to your needs.